With the increasing demand for street lighting, the market for its supporting products, street light poles material demand is also different. In fact, street light poles also have different material classifications, with the use of different places, the choice of material will be different.

1. cement light pole

The main composition of cement lamp pole is cement,sand and stone concrete.Formerly widely use in urban power towers and city street lamps. Because of its heavy weight, it’s not easy to install, and easy to weather and be broken by accident, there are safety risks. Has been phased out of the market.

2. steel light pole

Steel light pole made of high-quality material Q235 steel rolled. The surface treatment is different, and is divided into black pipe,galvanized pipe and hot-dip galvanized pipe. Black pipe surface finish with zin sprayed or plastic sprayed can be rust free for 1-2years use under normal environment.Galvanized pipe surface finish with plastic sprayed can be rust free for 2-3years use under normal environment. Hot-dip Galvanized pipe surface finish with plastic sprayed can be rust free more than 10 years use under normal environment. In the lighting project, the most commonly used Street light pole, high mast and power towers is the hot-dip galvanized pipe.

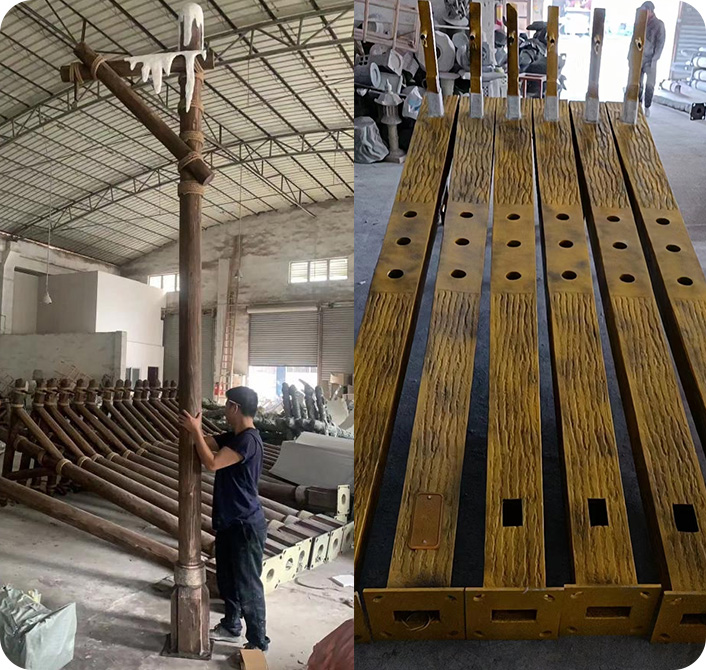

3. Glass fiber light pole

FRP light pole is a kind of inorganic non-metallic material with excellent performance.It’s advantages are good insulation,strong heat resistance and very malleable material.But its disadvantages are brittle and poor wear resistance.Therefore,it is generally used in theme parks,special shape landscape light products,not many are used for street light pole.

4. Aluminium alloy light pole

The aluminium pole is divided into casting aluminium pipe and extruded aluminium pipe.Casting aluminium pipe is made of die casting or sand casting.Widely used in the special shape of the European classical garden light pole.Extruded aluminium pipe is made of high-strength aluminium alloy.It’s high strength and safety.The surface has been anodized and finish color powder coating can be corrosion resistance for more than 30years.It looks more upscale.Widely used in modern garden light pole and flag pole.

5. Stainless steel light pole

Stainless steel light poles have the best chemical and electro chemical corrosion resistance in steel, second only to titanium alloy. Nickel content is different,and is divided into the commonly used 201,304 and 316 grades. Different grades of materials, the cost difference is relatively large.We can choose the appropriate grade of materials according to different use places and requirements. At present, 304 grade stainless steel pipe and sheet is the most widely used material in urban landscape lighting and urban sign lighting.

Post time: Nov-03-2022